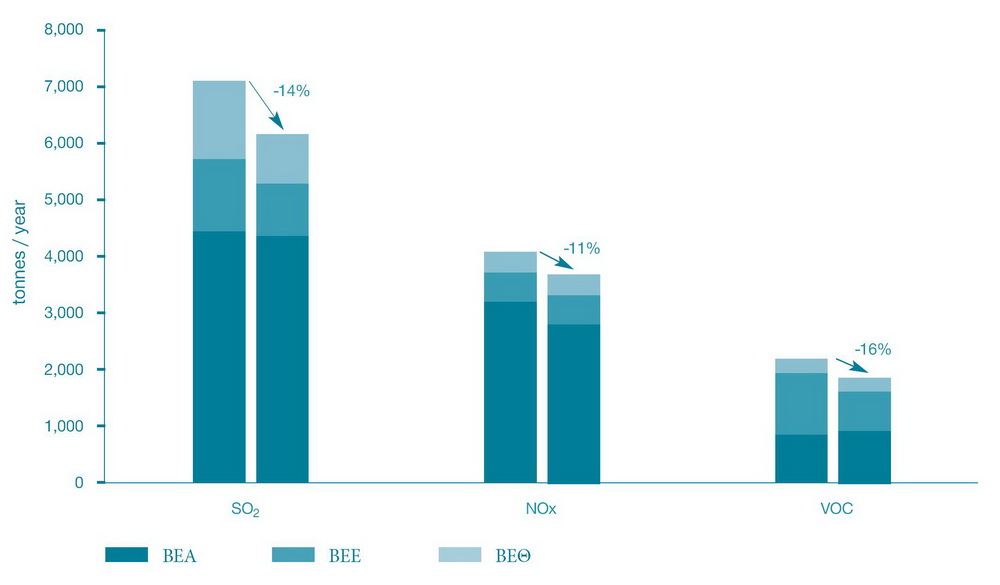

HELLENIC PETROLEUM aims at reducing both air emissions and waste generated, through specific actions; such as maximizing the use of gas fuels, the use of cleaner fuels and the implementation of advanced technologies in the production process. In 2014, at the three Group’s refineries, the most significant air emissions for the oil sector were reduced by up to 16%. These figures are presented in detail in Chart 4.5, for emissions of sulfur dioxide (SO2), Nitrogen Oxides (NOx) and volatile organic compounds (VOC).

Chart 4.5: SO2, NOx and VOC emissions

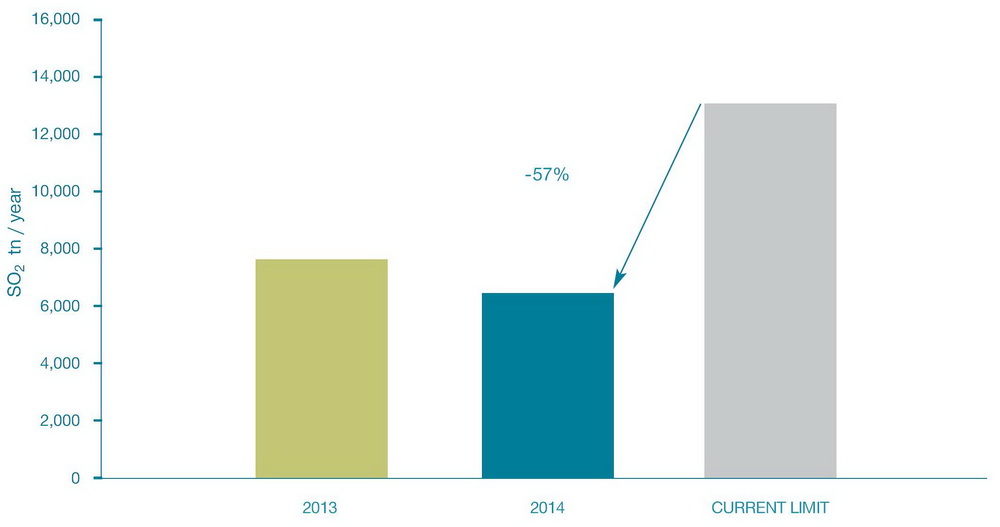

Indicatively, SO2 emissions remained much lower (-57%) than the environmental operating conditions’ current limit (in tn/year). Note that the above mentioned limit concerning on sulfur compounds emissions decreased in 2013 by 30% compared to the limit in force until 2012.

Chart 4.6: 2013-2014 SO2 emissions compared to current limit

As part of the broadening of clean fuel options, the Aspropyrgos refinery is already connected (2014) to the Greek gas network; the Elefsina refinery is in the process of being connected to the gas network.

With the full operation of the new Elefsina refinery, in 2014, the improvement at the refinery’s emissions was significant and exceeded the estimates of the approved Environmental Impact Study (EIS). Indicatively, emissions of sulfur dioxide (SO2) decreased by >80%, against 70%, while nitrogen oxides (NOx) emissions decreased by >30%, against the 11% estimated in the Environmental Impact Study. In addition, the air quality in the region significantly improved, according to the measurements recorded at the environmental station and the municipal station, where zero concentrations of SO2 were recorded and NOx concentrations of 78% below the relevant limit and 12% lower than the initial NTUA’s study estimated for the project were recorded.

Waste Management

With regard to the management of wastewater and solid waste, primary objectives include the prevention and minimization of production, the recycling as possible; and in situ management and treatment in the best possible way for both the environment and human health.

HELLENIC PETROLEUM has invested in modern waste treatment facilities, such as the 3-stage wastewater treatment units and the oily sludge treatment unit, using biodegradation technique, in the Thessaloniki industrial complex. The latter, in 2014, increased its efficiency significantly, by introducing the addition of specific bio-enhancing microorganisms in the process (bioaugmentation).

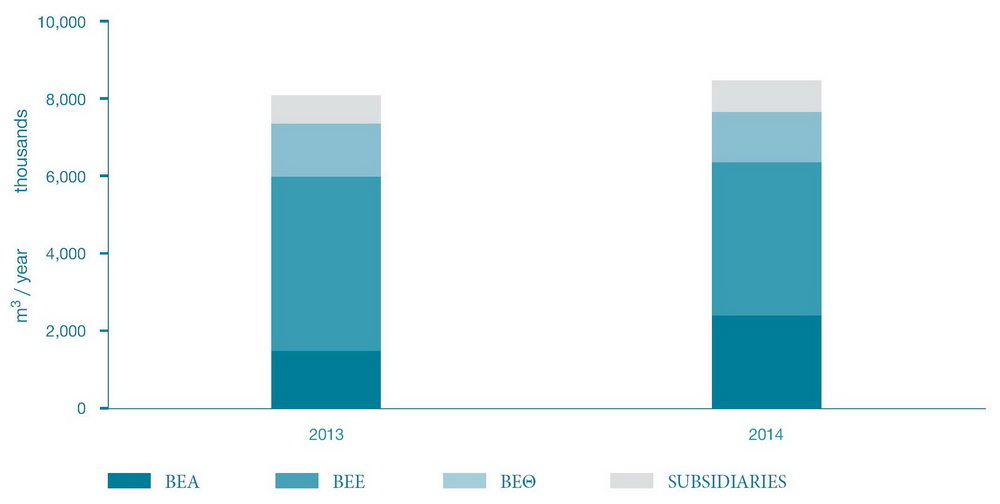

Chart 4.7: Wastewater per Group’s facility, 2013 vs 2014

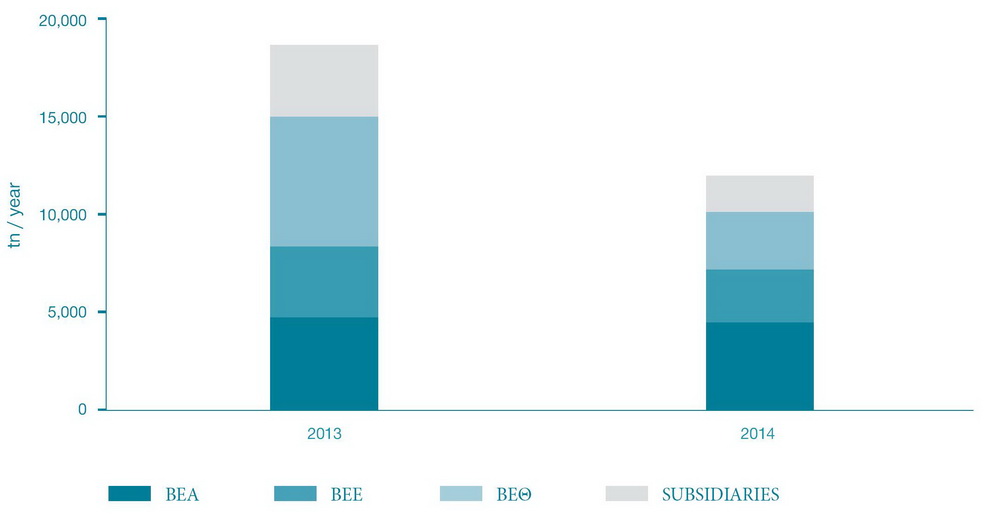

Chart 4.8: Solid waste per Group’s facility, 2013 vs 2014

Charts 4.7 and 4.8 present the comparison of the amounts of wastewater and solid waste, respectively. Noticeable is the 36% reduction in solid waste while wastewater showed a slight increase of around 5%, mainly due to the full operation of the Elefsina refinery.

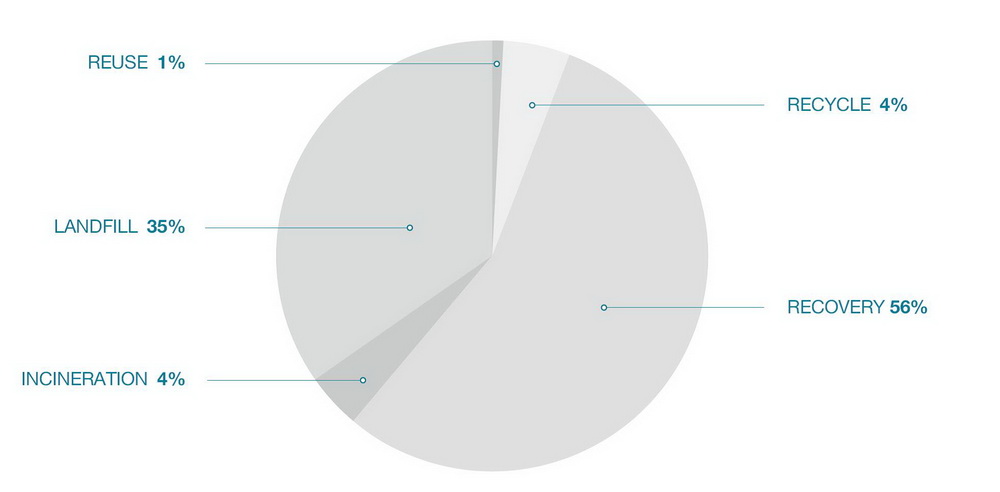

Chart 4.9: Group’s waste breakdown by disposal method

Chart 4.9 presents a detailed overview of the methods of disposal of solid waste. Over 60% of total waste was recycled, exploited through raw materials recovery processes and reused.

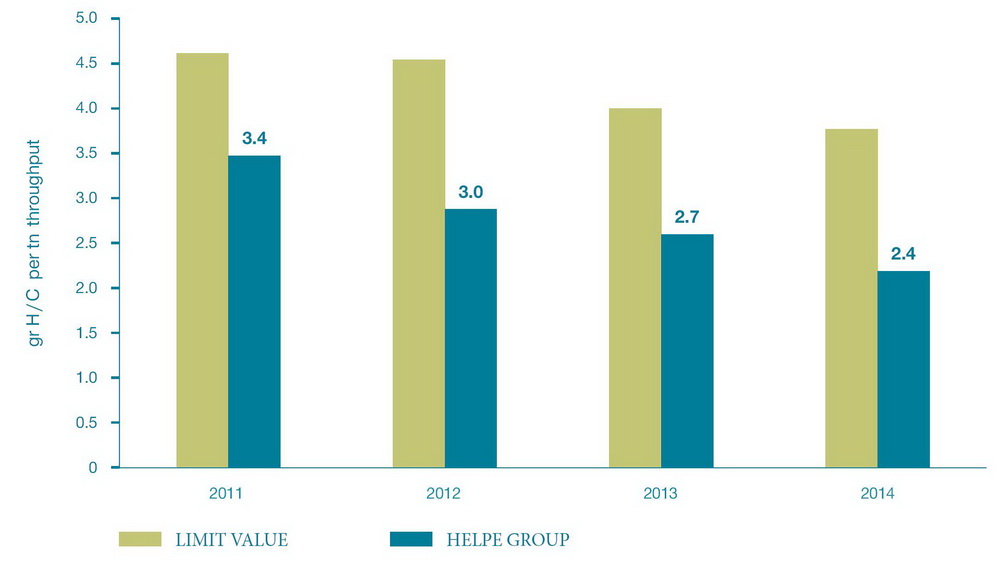

Moreover, improved performance in terms of the quality of treated effluents continues, in 2014, when the average index for hydrocarbons for the three Group refineries is calculated 40% lower than the statutory limit. Chart 4.10 presents the reduction trend (30%) over the last 4 years.

Chart 4.10: Group’s effluents hydrocarbons index, 2011-2014